ABSTRACT

As a result of climate change and the world´s population growth, ensuring sufficient amount of water is expected to be an increasing problem. There is a growing need for eco-technologies with reduced water consumption, for the use of harvested rainwater, as well as reuse of wastewater.

Currently there are millions of known chemicals, and more and more are being synthesized every day. The chemization of various branches of industry leads to the increasing massive contamination of our environment with foreign substances.

This paper presents the possibilities of rebuilding experimental laboratory equipment for the physical processing of waste into an equipment able to apply electrostatic field action on wastewater. It also considers the possibilities and perspectives of its further use, either alone or in combination with other technological processes, e.g. biotechnologies. The first series of experimental trials was aimed at eliminating selected pharmaceuticals.

INTRODUCTION

Classic mechanical-biological wastewater treatment plants (WTP) work well in most cases for basic pollution indicators (BOD5, CODCr, N-NH4+, Ntotal, Ptotal, NL); however, they are not efficient enough to remove specific organic contaminants, the so-called emerging contaminants (ECs). In the literature, this term refers to substances that are not or have not been sufficiently controlled by existing regulations. These substances pose a significant risk to the environment and to human health, and are also one of the reasons for limiting the reusability of treated wastewater. ECs also include pharmaceuticals and other personal care products (PPCPs). The removal or significant reduction of these substances in the effluent from a WWTP could be solved by an integration of another suitable type of treatment, mostly referred to in the literature as tertiary or quaternary treatment [1]. The use of advanced oxidation processes (AOPs), ozonation, adsorption, or a combination of these appears to be appropriate and promising. Technological treatment process must be well managed otherwise, in the case of incomplete, insufficient decomposition of organic micropollutants, new products might be created which often show significantly more toxic properties than the original substances [2, 3]. Besides efficiency of this process, also today´s economic factors play a significant role, such as the price of the technology itself, its operation, energy consumption, and shelf life.

Another possible method of tertiary treatment presented here is electrostatic field application performed either alone or in combination with other technologies, for example biotechnologies.

First information on the effect of various force fields (especially electromagnetic) on humans and the environment had already been published around 1960. Currently this option is explored by several institutions, either focused on the fields themselves or in combination with other technologies; some important publications see below in the references [4–9]. A new, original device called CaviPlasma, which combines hydrodynamic cavitation and plasma discharge, looks very promising. It resulted from collaboration of the University of Technology in Brno, Masaryk University, and the Institute of Botany of the Czech Academy of Sciences, p. r. i.

Between 2007 and 2011, within the framework of the MoE R&D project SP/2f2/98/07 “Research in utilization of waste as a substitution of primary raw materials”, the staff of TGM WRI Prague was developing the equipment for processing waste using physical processes. Its concept was registered as a utility model under registration number: Int. 21084, Industrial Property Office on 2nd July 2010 [10]. European patent EP 2388068 [11] was granted for the equipment and method of physical treatment of waste on 22nd August 2014. Equipment for the physical treatment of materials (especially solid waste matrices) conceptually consists of the individual or selected combined action of selected force fields (microwave field, ultrasound, UV radiation, spark discharge, electrostatic field, and others, if appropriate).

Technical Description of the Original Equipment

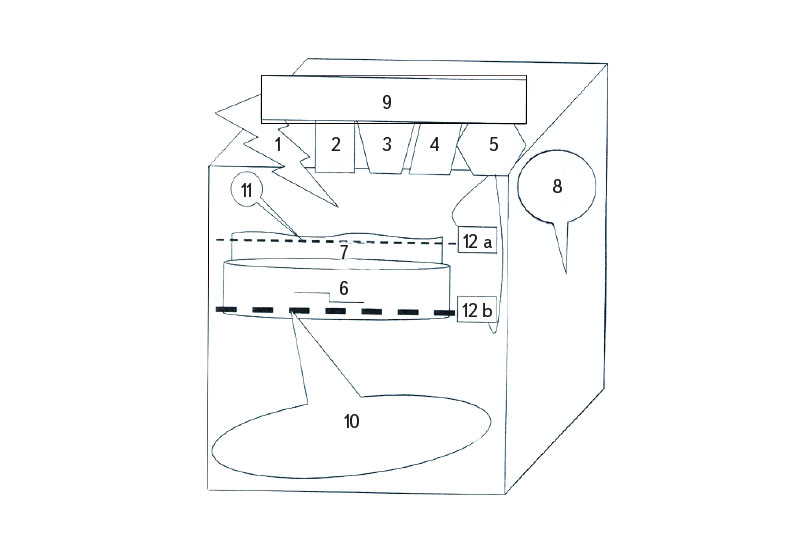

The designed device for physical treatment of waste has been assembled from individual generators of physical force fields placed in a transparent box with a woven grounded Faraday cage with an opening inlet – handling hole. A base made of non-conductive material is loosely placed at the bottom of the box, and a plastic container (vessel) for inserting the monitored matrix for sample exposure lies on the base. The bottom of the container is formed by thick layer of plastic with a very high ohmic resistance. An electrically conductive metal mesh is loosely placed on the bottom of the container during exposure to an electrostatic field. Above the vessel, there is a second metal mesh either dipped in the sample or freely suspended above the sample. Both meshes are connected by conducting wire to an electrostatic generator. The carrier bridge with a movement mechanism carries the UV generator and the spark discharge generator. The movement of the bridge is enabled by an electric drive that can change between two speeds of movement and between two directions (back and forth). When reaching the end of the defined driving lane, the direction of movement is automatically reversed using end-of-lane switches. Driving length is mechanically adjustable. Exposure by an electric spark discharge is done by a spark gap, which is also located on the carrier bridge. Force field generators can work simultaneously, in different combinations of sequences, or independently. Currently, it is not possible to enable the joint action of the force electrostatic field and the electrical spark discharge due to the risk of damage to the electronics by the spark discharge. Device diagram see Fig. 1.

Fig. 1. Diagram of device for physical waste pre-treatment

1, 2, 3, 4, 5 – force field generators (spark discharge, microwave field, ultrasound, UV radiation, electrostatic field), 6 – plastic vessel (container for a sample), 7 – sample investigated, 8 – Faraday cage, 9 – carrier bridge, 10, 11 – conductive metal mesh, 12a, b – HV supply cables

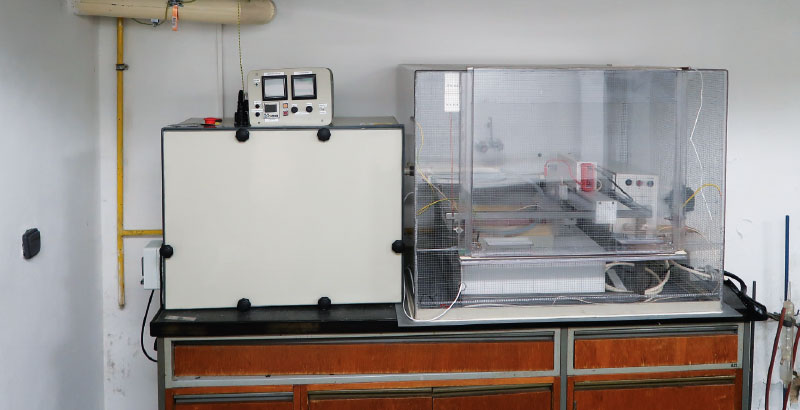

For experimental wastewater treatment activities, optimized equipment is used for physical waste treatment with a redesigned workspace for electrostatic field action. The reaction space is currently being refined. An experimental device for water purification using an electrostatic field see Fig. 2.

Fig. 2. Optimised testing/experimental equipment

Acting on wastewater using the above-described device with an electrostatic field may be suitably combined with other chemical or biochemical technologies and procedures. Biotechnologies seem to be feasible where physical procedures are used for initiation – opening and making matrices available for further action.

Biodegradations of dangerous harmful substances in the environment are important prospective methods, where complex compounds and pollutants harmful to the environment are broken down into simpler (harmless) substances by biological action of living microorganisms. The principle of biodegradation technologies is the optimization of nutrient ratios (to support the growth of selected microorganisms able to degrade target contaminants) and the application of appropriately selected isolated strains of microorganisms with the appropriate biodegradation capability [12].

Biological methods of decontamination use their own or inoculated microorganisms (fungi, bacteria and other microorganisms) to break down (metabolize) organic pollutants contained in soils, wastes, or waters.

When applying biodegradation methods, account should be taken of the fact that this process is very complex. Success or failure depends primarily on the following factors [13–15]: chemical (type of contaminant, environmental pH, concentration of macro and microbiological elements, water content, chemical composition of contaminated material, chemical composition and concentration of suitable nutrient solutions, etc.), microbiological (degradation activity of microorganisms), and physical (temperature, solubility in water, sorption to solid particles).

Given that each of the above-mentioned factors impact the course of biodegradation, it is obvious that, when designing technological procedures and their applications, these factors must be taken into account and, if necessary, modified so that they limit the biodegradation process as little as possible.

Wastewater samples both with and without physical pre-treatment were subject to laboratory biodegradation experiments in the premises of the Department of Environmental Engineering of VSB – Technical University of Ostrava. A mixture of Rhodococcus degradans, Rhodococcus rhodochrous, and Rhodococcus erythropolis bacteria obtained from the Czech collection of microorganisms kept by the Faculty of Science of Masaryk University in Brno has been used for biodegradation. The Czech collection of microorganisms has a considerable spectrum of various types of microorganisms, together with a supporting database which includes their degradation abilities and specific cultivation properties and conditions.

Part of the samples was biodegraded without pre-treatment; part was subject to physical pre-treatment before the actual biodegradation on the equipment for physical pre-treatment in the laboratories of TGM WRI. For pre-treatment, the effect of an electrostatic field was tested with different exposure times, voltage in the range of kV, electric current in the range of mA.

The actual biodegradation took place for three weeks. Afterwards, the samples were filtered and special chemical analyses were performed. Due to the characteristics of the given wastewater sample, approximately 70 substances from the PPCP group (mostly pharmaceuticals) were selected for chemical determinations.

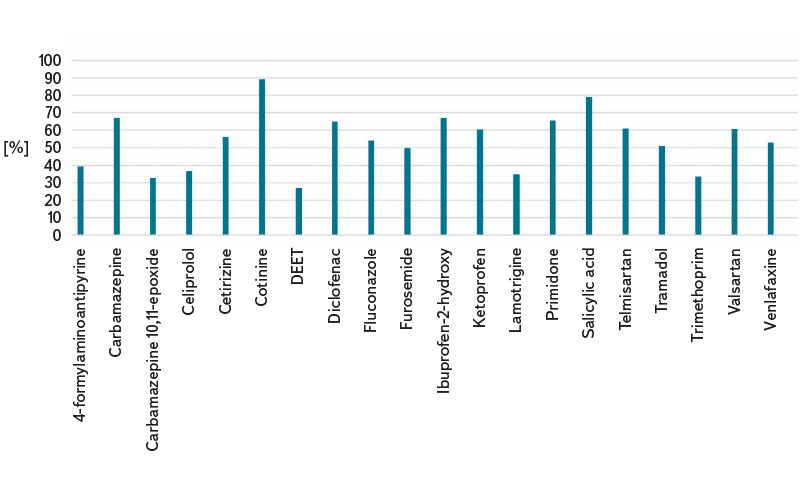

The first series of experiments indicate that just with the help of an electrostatic field, the content of active ingredients in many pharmaceuticals can be reduced (e.g., carbamazepine, celiprolol, clarithromycin, diclofenac, hydrochlorothiazide, iohexol, iomeprol, irbesartan).The combined technological procedure (physical treatment with an electrostatic field and biotechnologies with the help of selected strains of bacteria) appears to be very promising as a significant part of the entire spectrum of monitored substances has been reduced. Physical pre-treatment significantly increases the efficiency of subsequent biotechnologies by tens of per cent. The change (increase) in the efficiency of biodegradation of selected pharmaceuticals using an electrostatic field compared to biodegradation without the use of an electrostatic field is shown in the graph (Fig. 3).

Fig. 3. Change/Increase in biodegradation efficacy of selected pharmaceuticals using electrostatic field versus biodegradation without applying an electrostatic field [%]

Experimental activities have verified that the combination of physical pre-treatment and biodegradation can be carried out gradually, or, if appropriately chosen mode, in the simultaneous synergy of both processes.

This is a presentation of the first results of experimental activities, which means that it is early to draw final conclusions. Individual functional elements of the experimental device are still in the process of refinement (e.g., reaction cassette space, sample circulation, pump with operation control). The equipment for physical wastewater treatment with a high voltage source was prepared for technical inspection. Audit reports are being issued for the experimental equipment and the HV source. A utility model application is planned to be submitted for the registration of finally refined reaction space of the device.

It can be stated that the combination of physical pre-treatment and biodegradation procedures appears to be promising in terms of effectiveness and spectrum of action.

Experimental laboratory tests are currently being performed to improve functionality, determine conditions of use of the equipment to reduce selected substances (pharmaceuticals) in real samples of wastewater from municipal wastewater treatment plants alone or in combination with selected biotechnologies.

DISCUSSION AND CONCLUSION

Topical issue in water management sector is wastewater purification from micropollutants, which would reduce the load on nature caused by anthropogenic activities and, at the same time, enable to reuse water, which is why new techniques and technologies are welcomed and, at the right time, also supported by society within the framework of fulfilling the goals of sustainable development.

The current physical waste treatment equipment is modified to use an electrostatic field to reduce the content of selected persistent pollutants in wastewater. The equipment is currently constructed as a test laboratory device, but in the future it shall become an industrial device.

Currently, cooperation is being built with other research institutions (especially with remote sites at universities) and trial testing of wastewater is performed as part of user optimization of the equipment. Negotiations with manufacturers of test laboratory and industrial technical equipment (especially WWTPs) are underway. A network of professional partners is constantly expanding. To prepare a marketing strategy for the product, an important and strong strategic partner is being sought for the further development and application of this equipment.

Acknowledgements

This article was created as part of the work package WP 2. A of the Centre of Environmental Research “Waste Management, Circular Economy and Environmental Security (CEVOOH – SS02030008)” with the financial support of the Technology Agency of the Czech Republic within the frame of the second public tender of the Programme for the Support of Applied Research, Experimental Development and Innovation in the Field of Environment – Environment for life.

This article was translated on basis of Czech peer-reviewed original by Environmental Translation Ltd.